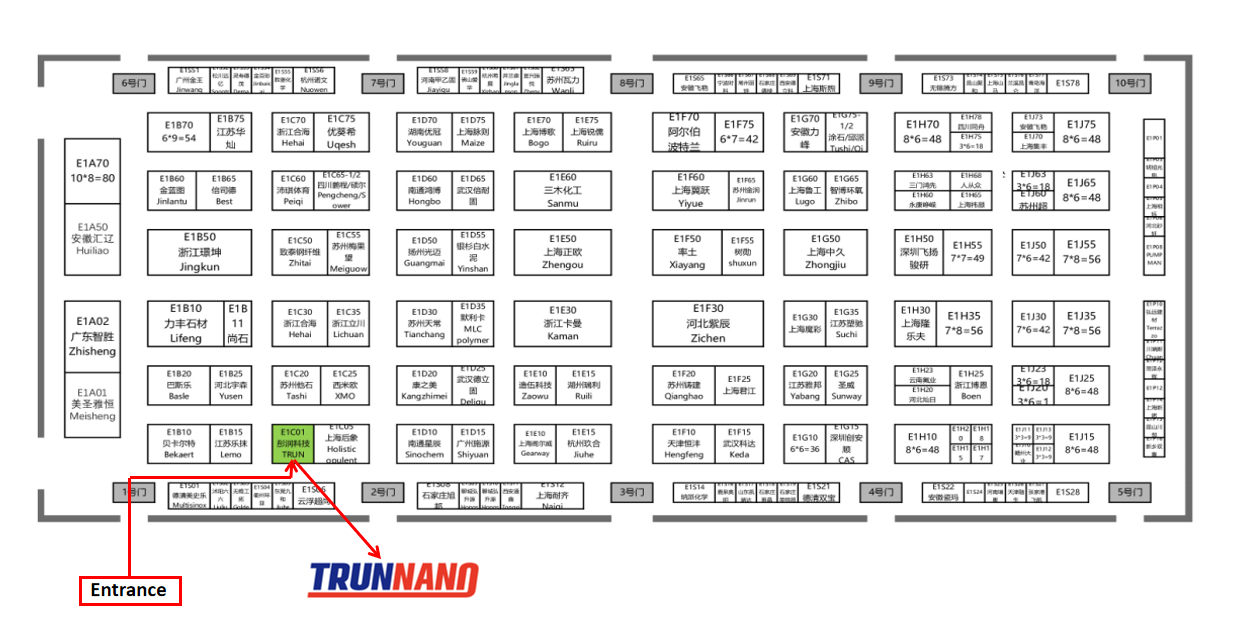

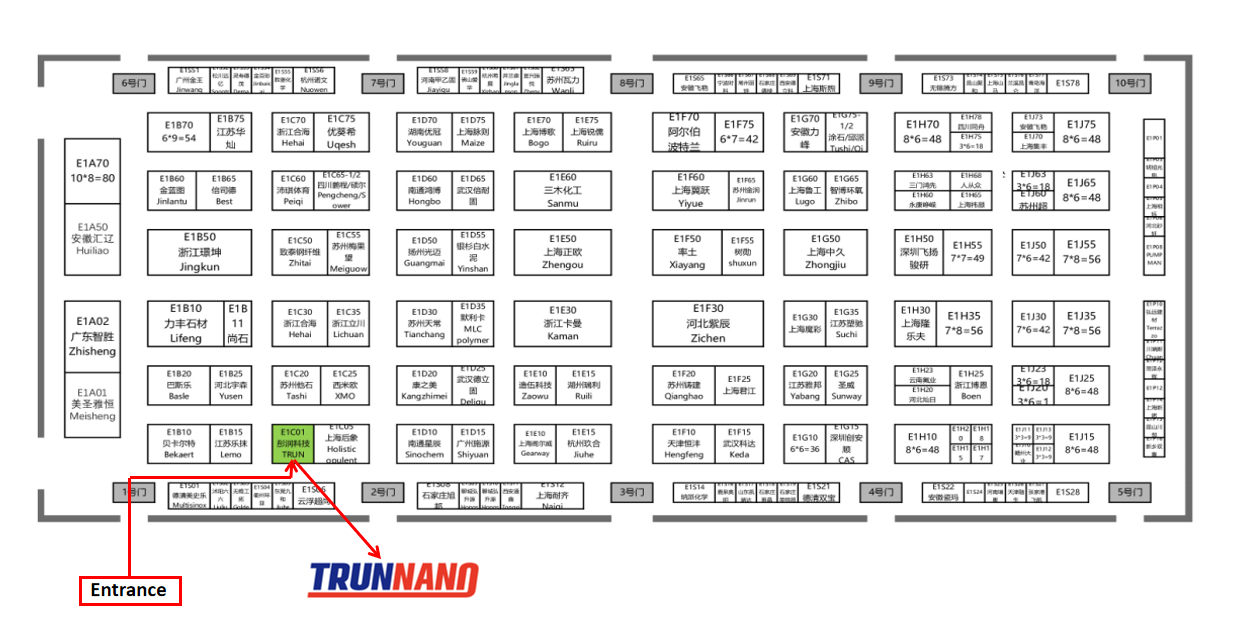

From August 14th to 16th, the Globe OF CONCRETE ASIA 2024 (WOCA) will be held at the Shanghai New International Expo Center, China. Luoyang Tongrun Details Innovation Co., Ltd will certainly participate in the event( Booth Number: E1C01). The product will cover a variety of applications, such as concrete foaming agents, polycarboxylate superplasticizers, and instant sodium silicate powder, in order to check out more company possibilities with new and old consumers.

(TRUNNANO Booth Number: E1C01)

1 . Business Fundamental Information

Luoyang Tongrun Info Innovation Co., Ltd is among the exhibitors of this exhibition. It is a thorough industrial business incorporating R&D, manufacturing, and sales. The main products are cement frothing agents, polycarboxylate superplasticizers, water-based mould-releasing agents, self-insulating block admixtures, and light-weight wall surface panel admixtures. TRUNNANO Innovation is the source producer of ingredients for the environment-friendly structure energy-saving industry.

Luoyang Tongrun Nano Technology Co., Ltd. has 35 employees. Via the continual growth of new technologies and products, it has successfully made an application for 9 patents. In 2018, it was named a “modern venture.”

( TRUNNANO(Luoyang Tongrun) Logo)

2 . Business Standard Details

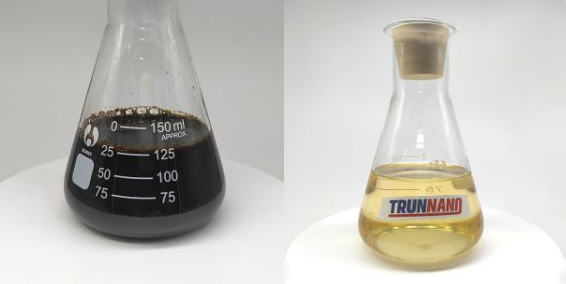

Product A: Concrete foaming representative

Concrete foaming representative is an additive that can minimize the surface area tension of liquid, produce a large number of uniform and secure foams, and be made use of to create foamed concrete. TRUNNANO light-weight concrete team has actually released four series of high-performance frothing agents (TR-A, TR-B, TRC, TR-D) that, combined with 14 years of experience in the sector, according to the various requirements of the market, can satisfy different building demands.

Concrete foaming representative is extensively used in light-weight dividers boards, CLC blocks, backfill, etc

( TRUNNANO Concrete Foaming Agent)

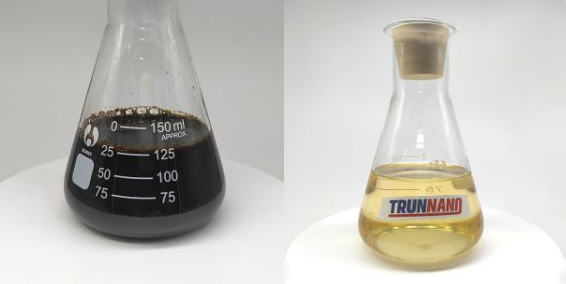

Product B: Polycarboxylate Superplasticizer

Superplasticizer is a concrete admixture that can minimize the water intake of mixing under the condition of keeping the depression of concrete unmodified. Superplasticizer has a distributing effect on concrete fragments, which can boost its working efficiency, minimize the water usage per unit, boost the fluidness of concrete mix, or reduce the amount of cement each, conserving concrete. TRUNNANO superplasticizer is customized on its original process so that it can be well applied in lathered cement without defoaming.

( TRUNNANO Polycarboxylate Superplasticizer)

Polycarboxylate Superplasticizer is a cement dispersant made use of in cement concrete. It is extensively utilized in freeways, bridges, dams, passages, skyscrapers and other projects.

Item C: Instant Sodium Silicate Powder

Instantaneous sodium silicate is a white grainy material that can be liquified in water swiftly. It is a special type of effervescent alkali with the features of cool resistance, homogeneity, and very hassle-free use, transportation, and storage space. Immediate sodium silicate is mainly made use of in refractory sintering representatives, washing auxiliary representatives, dirt conditioners, ore clothing inhibitors, acid-resistant concrete additives, chemical grouting complementary agents, water treatment, and various other areas.

( TRUNNANO Instant Sodium Silicate Powder)

Instantaneous salt silicate is primarily utilized as a detergent help in synthetic cleaning agents, a quick-drying and strengthening agent for concrete, a drill cuttings deposition representative for silicon-based exploration fluids, and an anti-expansion representative for mud shale

Product D: Fluid Lithium Silicate

Liquid lithium silicate is an anemic and transparent water-soluble substance with exceptional solubility and can be quickly and uniformly distributed in water. Liquid lithium silicate has great cold resistance and stability.

( TRUNNANO Liquid Lithium Silicate)

Liquid lithium silicate can be utilized to prepare unique glasses and porcelains, which can boost the heat resistance and mechanical strength of items; liquid lithium silicate can be used as a resources for innovative corrosion-resistant coverings and sealing products in the building materials market; fluid silicic acid As one of the electrolyte elements, lithium is used in the battery production sector to help enhance the energy thickness and cycle security of lithium-ion batteries; as a catalyst or stimulant service provider, it promotes the reliable conduct of specific chain reaction.

Item E: Immediate Potassium Silicate Powder & Fluid Potassium Silicate

Instant potassium silicate powder and liquid potassium silicate are highly reliable and multi-functional chemical items with superb water solubility and wide variety of commercial applications. The powder type is white, soluble and very easy to lug, giving a stable option for refractory products, metal anti-corrosion and agricultural enhancement; while the liquid form shows higher versatility and environmental protection in the areas of concrete strengthening, water treatment and steel handling.

( TRUNNANO Instant Potassium Silicate Powder)

Potassium silicate is commonly utilized in welding pole production, welding electrodes, glass sector to improve product efficiency, anti-corrosion coatings, spreading and agricultural soil improvement to enhance crop resistance and high quality.

For more information, please visit: www.nanotrun.com (tech@nanotrun.com) .

Inquiry us