Product Name: Calcium dodecyl stearate

Formula:(C18H35O3)2Ca

Molecular weight: 638.5

About Calcium Dodecyl Stearate:

Calcium Dodecyl Stearate, Chemical Molecular Formula: (C18H35O3) 2CA molecular weight: 638.5, for white to a light yellow fine powder.

Calcium dodecyl Stearate is a chemical substance of sheet or needle crystallization, a melting point of 82 to 93 ° C. Combustible, low toxic. Insoluble in water, dissolved in ethanol, diethyl ether and chloroform. Feel free to send an inquiry to get the latest price if you would like to buy Calcium Dodecyl Stearate in bulk.

If you want to know calcium dodecyl stearate price, please send inquiry to sales1@rboschco.com

Properties of Calcium dodecyl stearate:

Calcium dodecyl stearate is white to light yellow powder. It is insoluble in water, soluble in ethanol, ether and chloroform.

Technical Data of Calcium dodecyl stearate:

| Lose on drying | ≤5.00% |

| Calcium Content | 5.5-7.0% |

| Free Acid | ≤3.0% |

| Heavy Metal | ≤0.0010% |

| Particle Size | 200mesh passing≥99.0% |

How is Calcium Dodecyl Stearate produced?

The ricin oil is hydrogenated under the presence of nickel-aluminum catalyst, and the reaction product is soothered, and the product is obtained.

Application of Calcium Dodecyl Stearate:

Main uses of Calcium Dodecyl Stearate: Widely used in lubricants, stabilizers, plastics and rubber additives. As a thermostat, a plurality of plastic processed lubricants, release agents, is an excellent rubber and plastic aid. It is also used for organic synthesis.

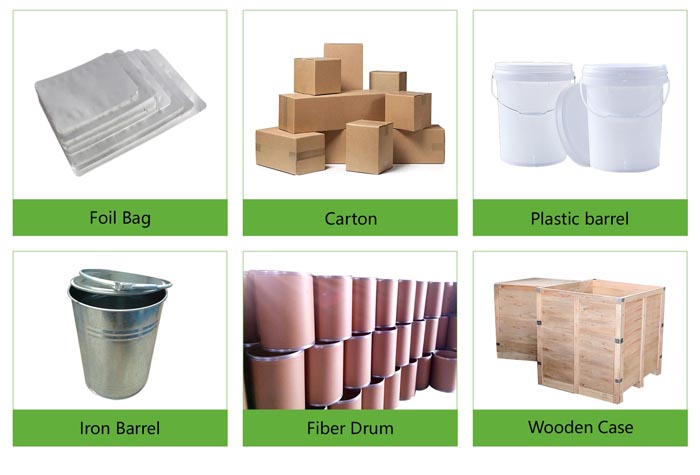

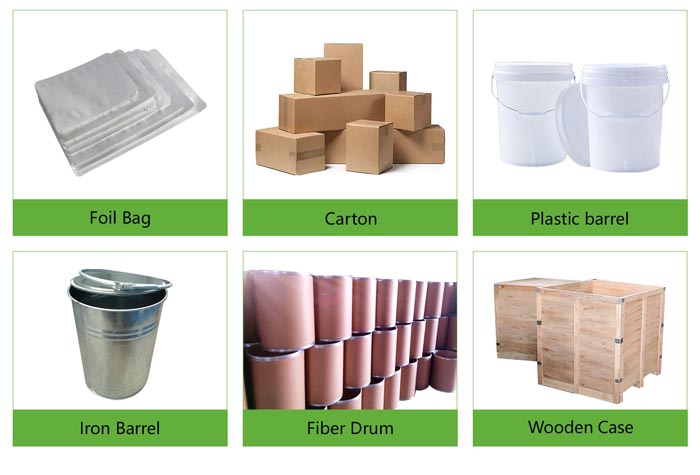

Packing & Shipping of Calcium dodecyl stearate:

We have many different kinds of packing which depend on the calcium dodecyl stearate quantity.

Calcium dodecyl stearate packing: 25kg/bag, or as your request.

Calcium dodecyl stearate shipping: could be shipped out by sea, by air, by express as soon as possible once payment receipt.

Calcium Dodecyl Stearate Properties | |

| Other Names | Chromium boride (CrB2), diboranylidynechromium |

| CAS No. | N/A |

| Compound Formula | (C18H35O3)2Ca |

| Molecular Weight | 638.5 |

| Appearance | white to light yellow powder |

| Melting Point | N/A |

| Solubility in water | N/A |

| Density | N/A |

| Purity | N/A |

| Particle Size | N/A |

| Boling point | N/A |

| Specific Heat | N/A |

| Thermal Conductivity | N/A |

| Thermal Expansion | N/A |

| Young’s Modulus | N/A |

| Exact Mass | N/A |

| Monoisotopic Mass | N/A |

Calcium Dodecyl Stearate Health & Safety Information | |

| Safety Warning | N/A |

| Hazard Statements | N/A |

| Flashing point | N/A |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | N/A |

| RTECS Number | N/A |

| Transport Information | N/A |

| WGK Germany | N/A |