About Iron Oxide Fe3O4 Powder

Iron oxide (II, III) (Fe3O4) is a highly insoluble and thermally stable iron source suitable for glass, optical and ceramic applications. Oxide does not conduct electricity. However, certain oxides of perovskite structure have conductivity in the cathodes of solid oxide fuel cells and oxygen generation systems.

They are compounds containing at least one oxygen anion and one metal cation. They are generally insoluble in aqueous solutions (water) and are very stable, making them useful for ceramic structures, as simple as the production of clay bowls for advanced electronic devices, and for lightweight structural components in aerospace and electrochemical applications such as fuels Batteries in which they exhibit ionic conductivity. Metal oxides are basic high-purity (99.999%) iron oxide (FeO) anhydrides, so they can react with acids and strong reducing agents in redox reactions. Iron oxide can also be made into particles, nuggets, powders, sputtering targets, tablets, and Nanopowders. In most cases, iron oxide is usually available immediately. High purity, submicron and Nanopowder forms can be considered. Provide other technical, research, and safety (MSDS) information. Feel free to send an inquiry to get the latest price if you would like to buy Iron Oxide Fe3O4 Powder in bulk.

How is Iron Oxide Fe3O4 Powder Produced?

Iron tetroxide is produced by the Schikorr reaction. This reaction converts iron (II) hydroxide (Fe(OH)2) into iron oxide (II, III) (Fe3O4). Under anaerobic conditions, ferrous hydroxide (Fe(OH)2) oxidizes in water to form magnetite and molecular hydrogen. Schikorr ‘s reaction explains this process.

3Fe(OH)2→Fe3O4 + H2 + 2H2O

Ferrous Hydroxide Magnetite Hydrogen Water.

Applications of Iron Oxide Fe3O4 Powder

Triferric tetroxide, commonly known as iron oxide black, magnetite, and black iron oxide, can be used in many different fields, for example:

Iron (II, III) oxide is used as a black pigment also known as Mars Black.

It is used in the Haber process as a catalyst.

It is used in the water-gas shift reaction.

Fe3O4 magnetic Nanoparticles are used in MRI scanning as contrasts against it.

It protects the steel from rusting.

It is an ingredient in thermite which is used for cutting steel.

Performance of Iron Oxide Fe3O4 Powder:

Ferric oxide has ferromagnetism. If the radius of the formed particles is on the nanometer level, it is called ferromagnetic particles.

Technical Parameter of Iron Oxide Fe3O4 Powder:

| Test item | 01 | 02 |

| Content Fe3O4≥﹪ | 99 | 99 |

| Moisture content ≤﹪ | 0.7 | 0.7 |

| Water Soluble ≤﹪ | 0.4 | 0.4 |

| Residue On Sieve(325mesh) | 0.3 | 0.3 |

| Oil absorption (ml/100g) | 21 | 21 |

| PH value | 7.0 | 7.0 |

| Tinting strength ﹪ | 99 | 99 |

Application of Iron Oxide Fe3O4 Powder:

1. can produce magnetic recording materials, high gradient magnetic separator, microwave absorption materials, special coatings.

2. widely used as a carrier for various pharmaceutical ingredients to form a magnetic targeting drug delivery system; used for the separation of magnetic immune cells, nuclear magnetic resonance imaging and other aspects.

3. used for precision instruments, gas seals, vacuum seals, etc.

Storage Condition of Iron Oxide Fe3O4 Powder:

Iron Oxide Fe3O4 Powder should be stored in dry, cool and sealing of the environment, can not be exposure to air, in addition, should avoid the heavy pressure, according to ordinary goods transportation.

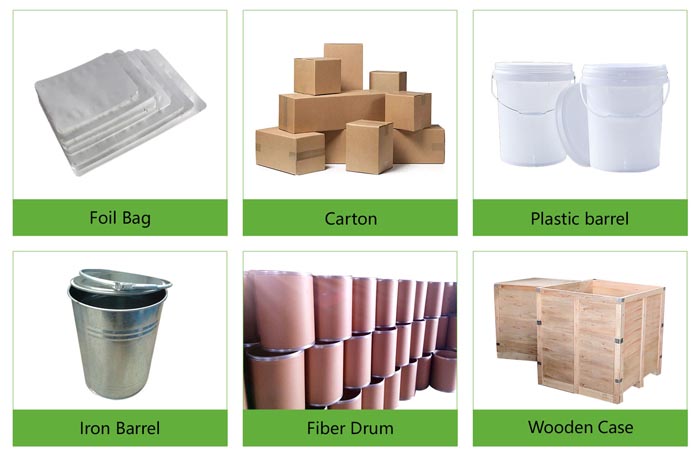

Packing & Shipping of Iron Oxide Fe3O4 Powder:

It is packed in double plastic bags inside, which can be filled with argon in vacuum; it can be vacuumed and filled with argon for protection.

Iron Oxide Fe3O4 Powder packing: vacuum packing, 100g, 500g or 1kg/bag, 25kg/barrel, or as your request.

Iron Oxide Fe3O4 Powder shipping: could be shipped out by sea, by air, by express as soon as possible once payment receipt.

Iron Oxide Properties | |

| Other Names | magnetic black, fenosoferric oxide, ferro ferric oxide, ferrosoferric oxide, Fe3O4 |

| CAS No. | 1317-61-9 |

| Compound Formula | Fe3O4 |

| Molecular Weight | 233.53 |

| Appearance | Black Powder |

| Melting Point | 1597 °C |

| Boiling Point | N/A |

| Density | 4.8-5.1 g/cm3 |

| Solubility in H2O | N/A |

| Exact Mass | 231.784471 |

Iron Oxide Health & Safety Information | |

| Signal Word | Warning |

| Hazard Statements | H315-H319-H335 |

| Hazard Codes | N/A |

| Risk Codes | N/A |

| Safety Statements | N/A |

| Transport Information | NONH |